liv eco habitats

TECHNOLOGY

TECHNOLOGY

Automated industrialization 4.0 (Artificial Intelligence, Robotics, Internet of Things) using modular construction systems in metallic structures, with the following competitive advantages:

Lightning Delivery | 2 to 4 months from the conception of the executive project, manufacturing, logistics and complete installation on site {electrical (photovoltaic) and sustainable hydraulics (ECTEs, Compact Effluent Treatment Stations)};

Structural Relocatability | repositionable eco habitats according to the geolocation chosen by the client;

Economic Promotion | budget predictability by scaled cost matrix and feasibility through rental or leasing;

Regulatory Compliance [ABNT NBR 15575] standardized processes [ISO 9001 (Excellence of Processes and Materials) and 14000 (Sustainability Seal]};

Preventative Maintenance Plan [PMP] structural warranty and conservation procedures;

Property Insurance Policy [ASP] provided by partner entities;

Construction system

MODULAR

The modular construction system is an approach in civil construction that involves the use of prefabricated or pre-assembled modules in a factory, which are then transported to the construction site and assembled to form the final structure. This technique differs from the traditional construction method, in which components are generally manufactured on site.

Characteristics

Prefabrication:

- The structure components are manufactured in a factory under controlled conditions, which allows for greater precision and quality in production.

- Materials such as steel, concrete, wood, fiberglass-reinforced plastic and others can be used to manufacture the modules, depending on the needs and specifications of the project.

Standardization:

- The modular system is often based on predefined standards and dimensions to ensure compatibility and ease of assembly.

- Standardization facilitates mass production and reduces the time required for design and manufacturing.

Efficient transportation:

- Prefabricated modules are designed to be easily transported to the construction site. This can reduce costs associated with transporting materials and optimize logistics.

Quick assembly:

- At the construction site, modules are assembled efficiently, often in a short period of time. This can result in significant time savings compared to traditional construction methods.

Flexibility and expandability:

- The modular system offers flexibility as modules can be customized to meet different needs and design requirements.

- Building expansion is generally easier as new modules can be added as needed.

Sustainability:

- Factory production can be more resource and energy efficient than traditional construction methods.

- Additionally, the ability to reuse modules across different projects contributes to sustainability.

Quality control:

- Manufacturing in a controlled environment allows for greater quality control, reducing the risk of errors in construction.

Construction materials

VETRORESINA

Vetroresina is a composite material made from thin, flexible glass fibers, generally combined with a polymer (resin), forming a resistant and lightweight composite.

Benefits

Lightness: It is a light material, which makes it easier to handle, transport and install. This characteristic is especially valuable in applications where weight is an important consideration, such as in the manufacture of aerospace, automotive and marine components.

High Strength: Although it is lightweight, vetroresin is known for its high strength. It is corrosion resistant, making it a durable choice in harsh environments.

Thermal and Acoustic Insulation: Fiberglass is an effective insulator in thermal and acoustic terms. This makes it useful in insulation applications in buildings, vehicles and equipment.

Electrical Resistance: It is an effective electrical insulator, making it suitable for applications where it is necessary to prevent the conduction of electricity.

Durability: It is durable and can have a long lifespan with proper maintenance. Its resistance to environmental factors, such as sunlight and humidity, contributes to its durability.

Sustainability: It is recyclable, which contributes to environmental considerations and sustainable practices in construction and manufacturing.

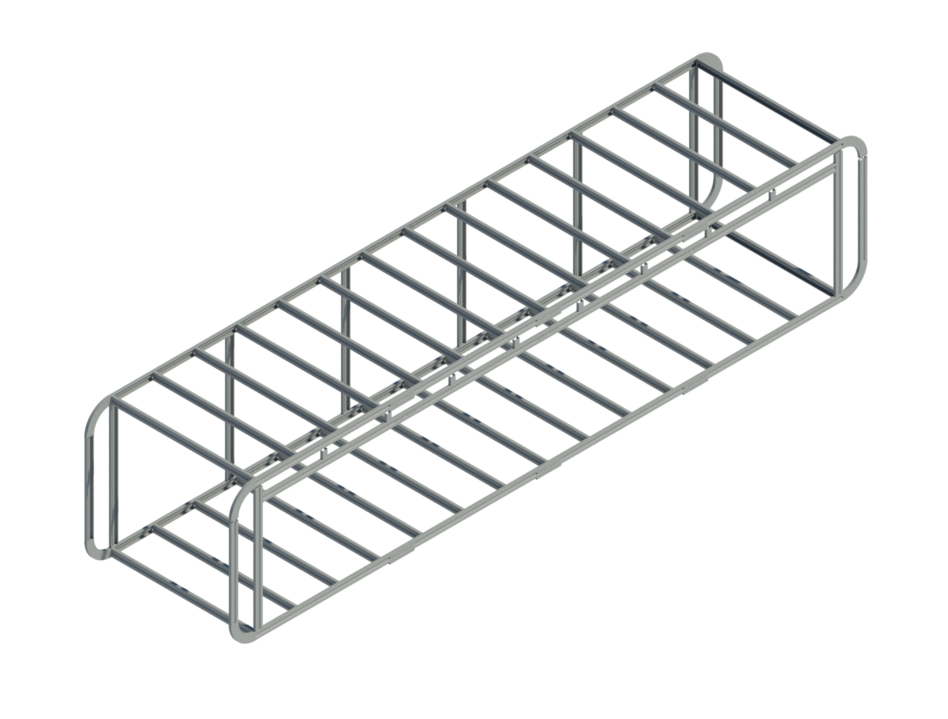

METAL STRUCTURE

Metallic structures are construction systems that use elements made of steel to support loads and provide stability to buildings, bridges and other constructions. Steel is a widely used material due to its mechanical properties, such as strength, durability and malleability. Here are some characteristics and advantages of metal structures:

Resistance and Durability:

- Steel is known for its high strength and durability, which makes it an ideal material for supporting heavy loads and withstanding harsh conditions.

Lightness and Stability:

- Despite its high strength, steel is a relatively light material, which makes it easier to transport and assemble metal structures.

- Metal structures also offer significant stability, allowing for larger spans without the need for intermediate columns or pillars.

Speed in Construction:

- The manufacturing of steel components can be carried out in a controlled environment, which allows for fast and efficient production.

- On-site assembly is also quick, resulting in shorter construction times compared to traditional methods.

Design Adaptability and Flexibility:

- Metal structures are highly adaptable to different architectural designs, allowing for a wide variety of shapes and styles.

- The flexibility of steel makes it easy to modify and expand existing structures.

Recyclability:

- Steel is a highly recyclable material. The ability to recycle steel reduces environmental impacts and promotes sustainable construction practices.

Fire resistance:

- Although steel is not non-combustible, it maintains its structural resistance to high temperatures for a considerable period of time, providing time for evacuation and fire response.

Reduced Maintenance:

- Metal structures generally require less maintenance over time compared to some other material options.

Space Saving:

- Due to their high strength, steel structural elements can be slimmer and take up less space compared to less strong materials.

Standardization:

- Mass production and standardization of steel elements can result in lower costs and greater efficiency in manufacturing and assembly.

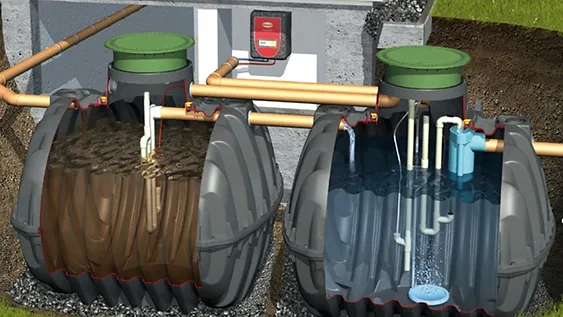

BIOREACTORS

Coupled rainwater reuse system for hydraulic and external applications, integrating an autonomous organic effluent treatment station using compact biological systems.

RENEWABLE ENERGY

Solar electric platform using thermal hybrid prisms.

HYDROGEN ELECTRIC GENERATOR

Power backup for additional emergency interconnection by electrical and hydrogen generators (fuel cells).